Viglacera Pioneers Full-Electric Low-Pressure Die Casting Technology for Faucet Manufacturing in Vietnam

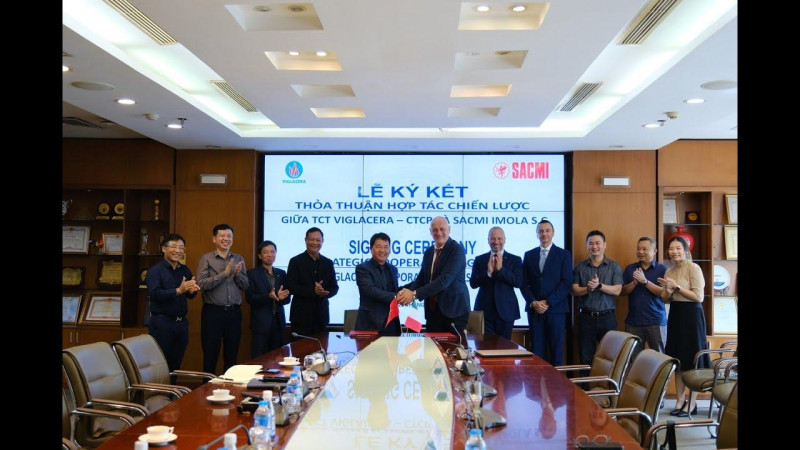

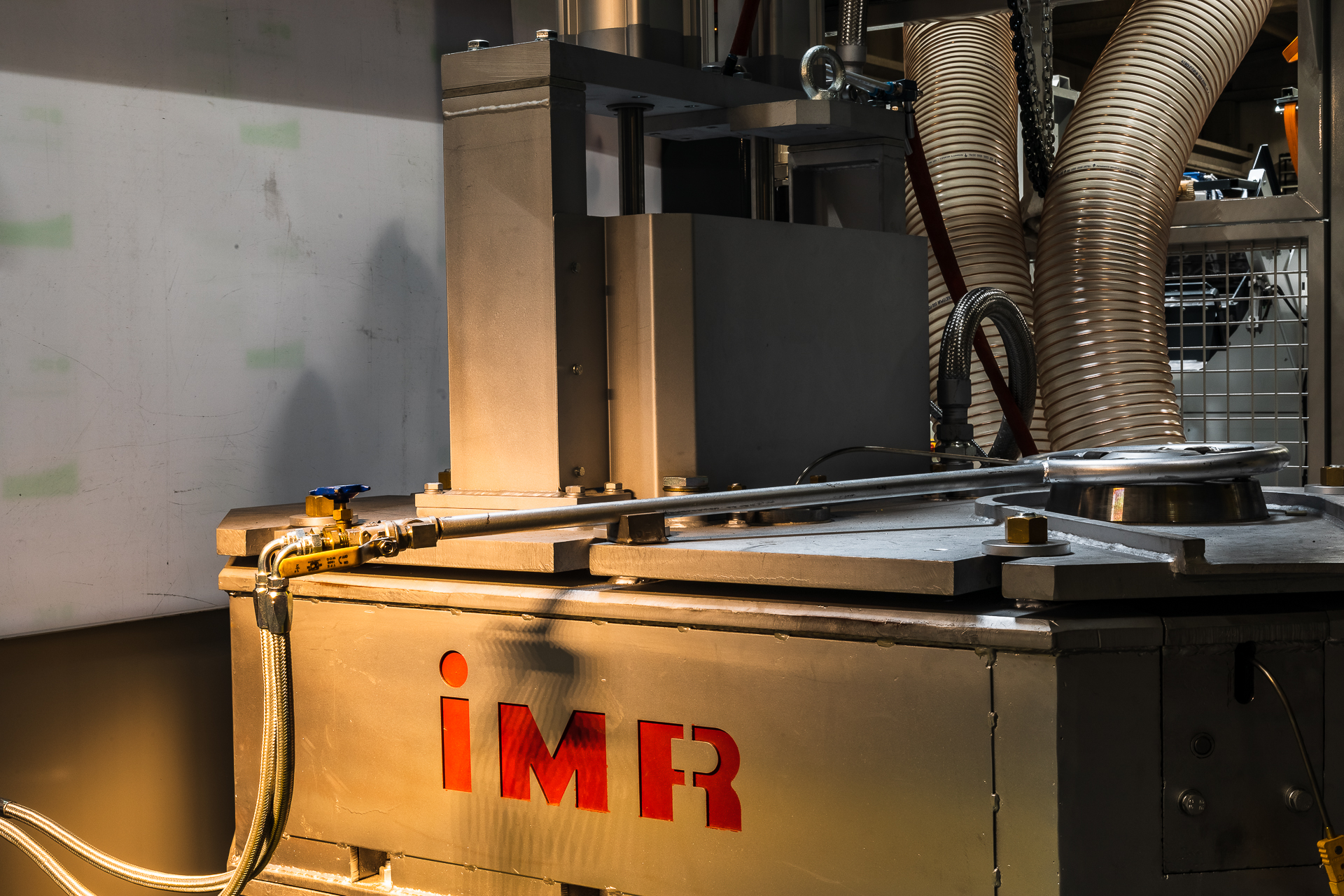

As part of its commitment to green and sustainable manufacturing, Viglacera has become the first enterprise in Vietnam to adopt a full-electric low-pressure die casting (LPDC) system and fully automated sand core making machine for the production of faucets. This milestone is made possible through a strategic technology transfer from IMR Engineering & Technologies S.R.L, an Italian leader in advanced die casting solutions.

Revolutionizing the Core of Faucet Manufacturing

While surface technologies such as PVD (Physical Vapor Deposition) have been widely recognized for improving aesthetic quality and durability, the core structural integrity of a faucet begins with its casting process. Viglacera’s LPDC system introduces a new standard for the Vietnamese sanitary industry.

The full-electric LPDC system injects molten metal from the bottom up using low pressure—producing high-density, low-defect castings while optimizing material use and enabling premium faucet designs

Unlike conventional gravity casting, the LPDC method uses low pressure and upward metal injection into the mold. The full-electric system ensures: Higher density and precision in casting, minimizing porosity and structural defects; Material savings, reducing brass consumption and overall production waste; Superior mold filling control, enabling complex, high-end product designs.

More importantly, the entire system is electrically powered instead of relying on gas or fossil fuels — significantly cutting down on CO₂ emissions and workplace noise, aligning with global standards for environmental responsibility.

Automation as the Future of “Made in Vietnam” Faucets

The new technology is not only eco-friendly but also boosts productivity—requiring just one operator instead of 3–5 workers compared to traditional gravity casting systems

In addition to the casting process, Viglacera has also integrated a fully automated sand core machine, which allows for: High-speed, consistent production, ideal for export-scale volumes; Minimized manual labor, enhancing workplace safety and accuracy; International compliance, meeting strict requirements from Europe, Japan, and the Middle East.

This transformation aligns with a global movement toward smart, green manufacturing — a future where industrial development goes hand in hand with environmental stewardship.

Setting New Standards for Vietnamese Sanitary Ware

Faucets with PVD coating offer exceptional surface protection, enhanced durability, and a refined, long-lasting aesthetic finish

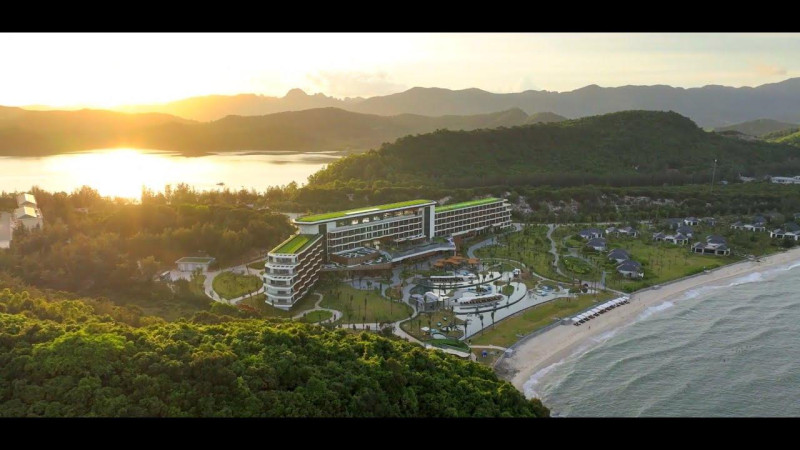

By combining LPDC and PVD technologies, Viglacera is building a new ecosystem of green faucets: “durable from the core, beautiful on the surface.” These innovations offer tangible benefits for both consumers and the environment: Stronger, longer-lasting faucets, ideal for both domestic and resort applications; Visually refined finishes, resistant to corrosion, scratches, and discoloration; Competitive pricing, thanks to localized production efficiency.

Lower environmental footprint, contributing to Vietnam’s broader sustainability goals.