Viglacera pioneers green technology – full electric low pressure die casting in faucet production in Vietnam

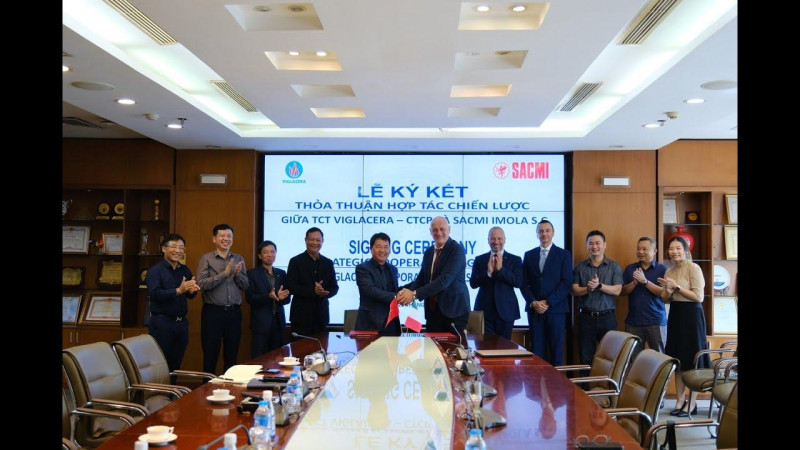

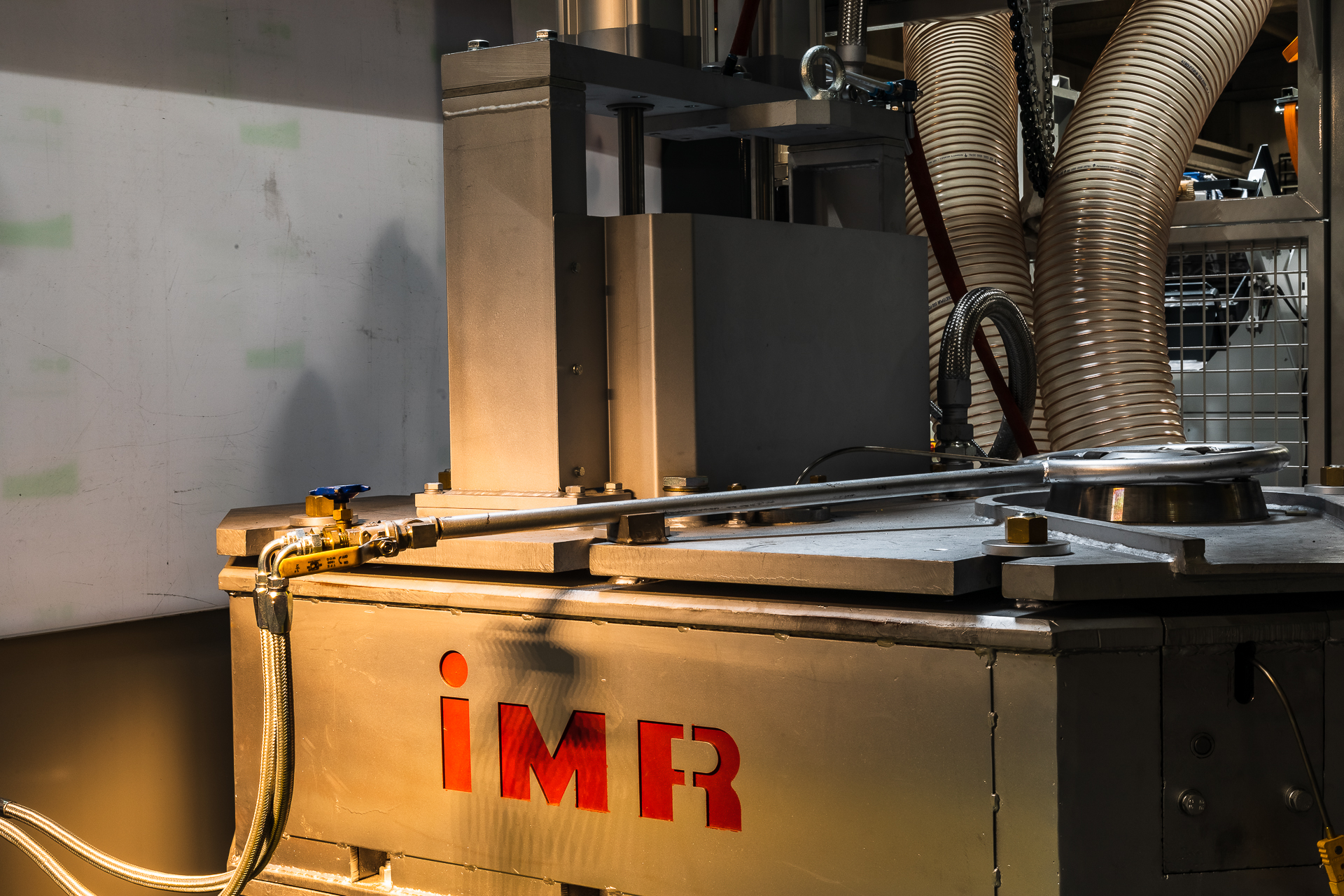

On the journey of “greening” the sanitary ware industry, Viglacera continues to mark an important milestone by officially putting into operation the full electric low pressure die casting (LPDC) system and automatic sand mold making machine, installed for the first time in Vietnam. This is the result of a strategic cooperation between Viglacera and IMR Engineering & Technologies S.R.L – a leading Italian enterprise in modern casting technology.

Low pressure die casting – the “heart” of high-quality “made in Vietnam” faucets

If PVD coating technology brings outstanding aesthetics and durability to the faucet surface, then low pressure die casting plays a decisive role in the “internal structure” – which makes the difference in solidity, uniformity, and performance of the product.

Unlike traditional gravity casting methods, the LPDC system uses low pressure and is fully electrically controlled to push molten metal into the mold from the bottom up. This process helps: Create products with high density, fewer air pores, and minimized technical defects; Reduce material waste, helping to optimize production costs; Increase accuracy, allowing flexible design of sophisticated faucet models in line with premium consumption trends.

In particular, the system runs on electricity instead of gas or oil, contributing to reducing CO₂ emissions, being more environmentally friendly and safer for operators.

Automation and global trends in the faucet industry

Along with LPDC, the automatic sand mold making machine is also integrated into the production line, helping to: Increase production speed, reducing reliance on manual labor; Ensure consistency and uniformity, even with large orders; Meet strict standards from export markets such as Europe, Japan, and the Middle East.

According to many experts, the application of LPDC in faucet production is an inevitable step that global brands have adopted for a long time to comply with green manufacturing standards – energy saving and safe for consumers’ health.

Viglacera – the Vietnamese enterprise leading the “greening” trend in the sanitary ware industry

With the investment in LPDC casting technology to strengthen the copper core and PVD coating to enhance durability and aesthetics of faucet surfaces, Viglacera is forming a product ecosystem with faucets “green from core to surface,” meeting both technical requirements and aesthetic value. From there, providing consumers with: Durable – beautiful – safe products, long-lasting as new; Reasonable prices, because they are produced directly in Vietnam; Sustainable living value, where consumption also means contributing to environmental protection.

Not stopping at production, Viglacera is pioneering in creating new standards for the Vietnamese sanitary ware industry – where technology, social responsibility, and user experience intersect to create “Made in Vietnam” products truly worth being proud of.

Additional information:

The full electric LPDC system & automatic sand mold making machine are installed at Viglacera’s faucet production plant. This is the 17th machine in the world, the only one in Vietnam.

Technology transferred by IMR (Italy), currently only present in developed industrial countries such as Germany, Italy, Japan.